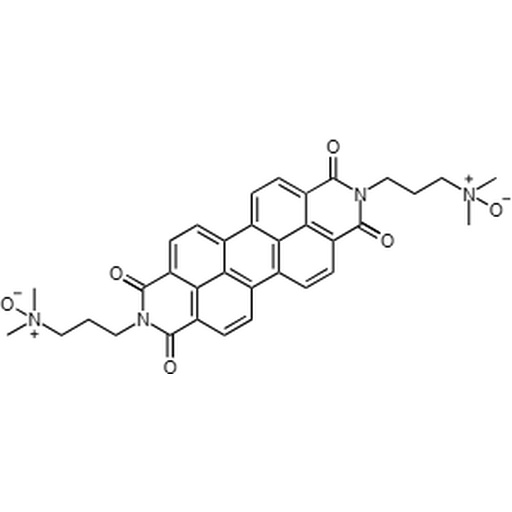

PDINO

| CAS number: | 1558023-86-1 |

![Compound PDIN, 117901-97-0, N,N'-Bis[3-(dimethylamino)propyl]perylene-3,4,9,10-tetracarboxylic diimide](https://noctiluca.old.semidea.pl/wp-content/uploads/2023/02/PDIN.jpg)

PDIN

| CAS number: | 117901-97-0 |

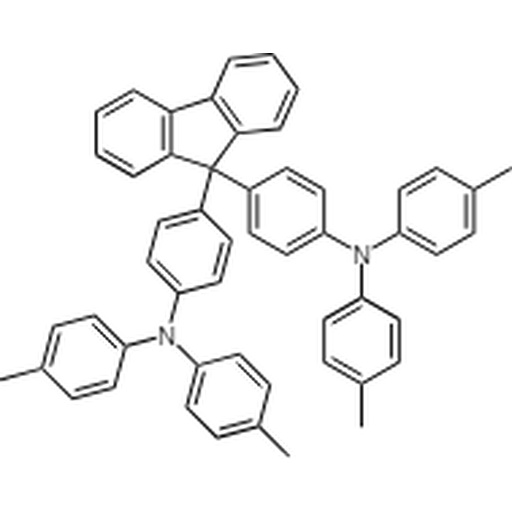

DTAF

| CAS number: | 159526-57-5 |

Transport layer materials are organic compounds responsible for charge transport within the OLED structure—both for electrons (ETM) and holes (HTM). Proper selection of these materials is essential for device performance, turn-on voltage, and operational stability.

We offer materials for HTL (Hole Transport Layer) and ETL (Electron Transport Layer), as well as compounds supporting electron injection layers (EIL) and electron blocking layers (EBL). Our portfolio includes a wide range of compounds, from well-established to next-generation structures.

The HTL layer is responsible for transporting holes (positive charge carriers) from the anode to the emissive layer. Its role is to ensure high charge mobility, energy level alignment, and to reduce recombination outside the emissive layer (EML).

ETL (Electron Transport Layer) is responsible for efficiently delivering electrons from the cathode to the emissive layer. It must feature a low LUMO level, good thermal stability, and compatibility with adjacent materials.

Important parameters include: HOMO/LUMO levels, charge carrier mobility, thermal stability, sublimation temperature, and compatibility with emissive layers and electrode materials. Material choice depends on the architecture of the entire OLED system.

Yes — a proper choice of transport layers helps to optimize charge balance, which leads to reduced overheating, longer device lifetime, and lower operating voltage.

Noctiluca’s collection includes TTPA, BPPB, B₂PymPm, BPhen, BCP, TPD, TSPO1, and TCNQ—used as HTL, ETL, EIL components and as barrier materials in OLED structures.

Yes, many of our transport materials are available in sublimed grade (≥99.9%), suitable for thin-film deposition in vacuum processes.

Yes — our transport layer materials are designed and selected to ensure compatibility with a wide range of commercial and custom OLED emitters, including both TADF and phosphorescent types.

Yes, we provide technical assistance in selecting the appropriate transport material, taking into account energy levels, application requirements, and compatibility with other OLED layers.

The standard purity of our materials is ≥99.5% (HPLC), and sublimed versions reach ≥99.9%, meeting the requirements of OLED and organic electronics applications.

Of course. We offer transport materials in mg–g quantities, ready for lab testing, prototyping, and initial deployments. On request, test series can also be prepared.

Yes — many of our materials offer high transparency and favorable optical properties, allowing their use in top-emission OLED.

Yes, as part of our custom synthesis service, we can design and produce transport materials with specific parameters tailored to defined architectures or customer requirements.

Just contact us — after confirming technical requirements, we will prepare a delivery offer, quality documentation, and a cooperation proposal. We serve both R&D clients and industrial partners.

©2025 noctiluca. All rights reserved.

General Contractual Terms and Conditions and Information for Customers | Privacy policy

Made with passion by Panda Marketing